Week 8

CNC milling, molding & casting

Assignment Prompt

-

Create something by molding and casting.

-

Design something and make it using CNC. You may use the ShopBot (2D outlines), the Shaper (2D outlines) or the SRM-20 (2.5D molds).

Inspiration

-

For the molding and casting, I wanted to make another one of my little buddies: Smiskis. I decided to imprison him in clear silicon to create a mold with which I would produce my wicked army of little men from.

-

For the CNC milling assignment, I wanted to use the Shaper to make a mini hangboard as an attachment for my final project.

-

Molding

-

Preparation

-

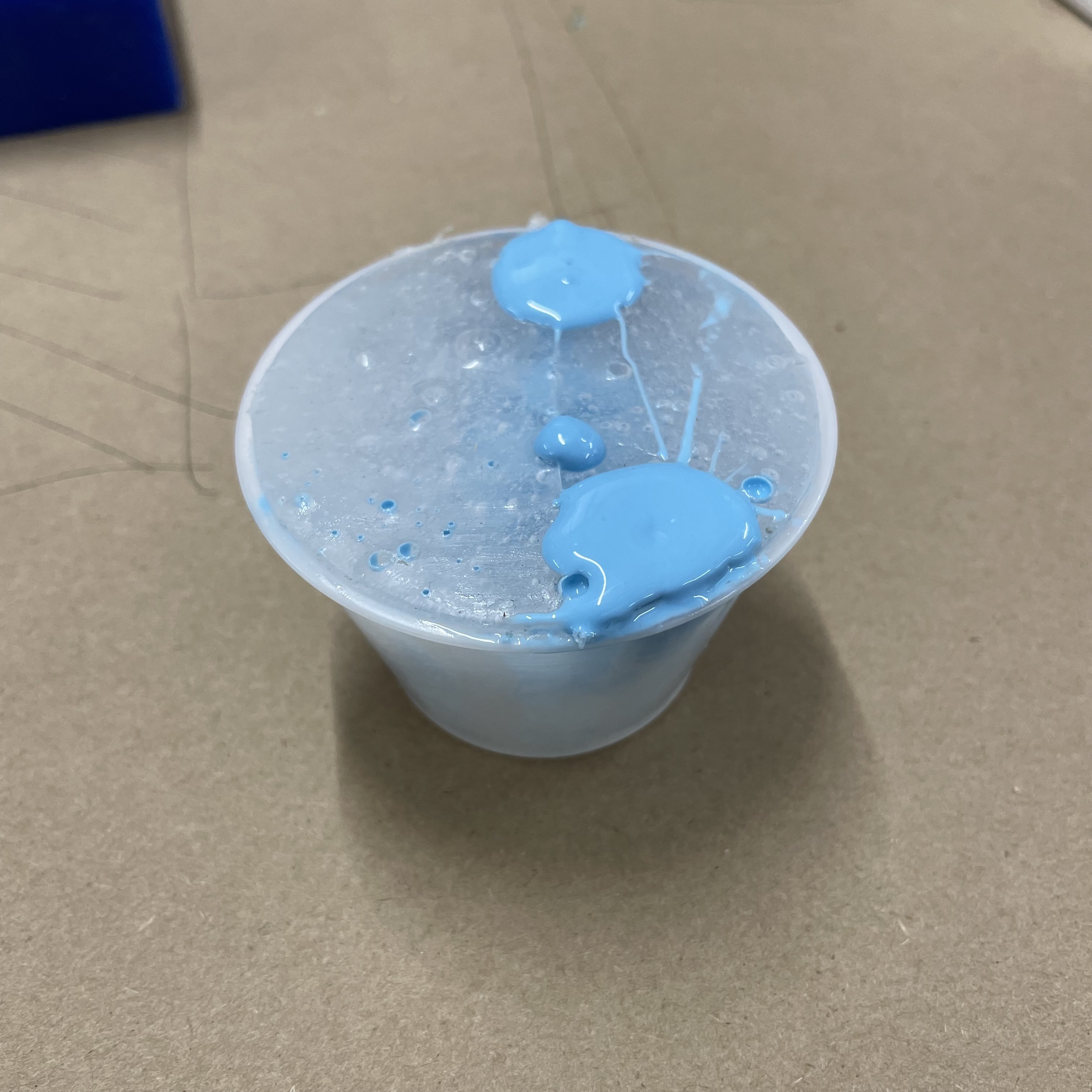

My silicon prison, the wicked contraption from which I will raise my army, cured overnight with one smaller straw as an air hole and another, larger one as a pouring hole. I positioned the Smiski upside down in the mold in order to let the silicon pour more evenly. I used one of the small plastic cups as an apparatus for the mold since it was a nice size and would be easy to cut out when the time came.

-

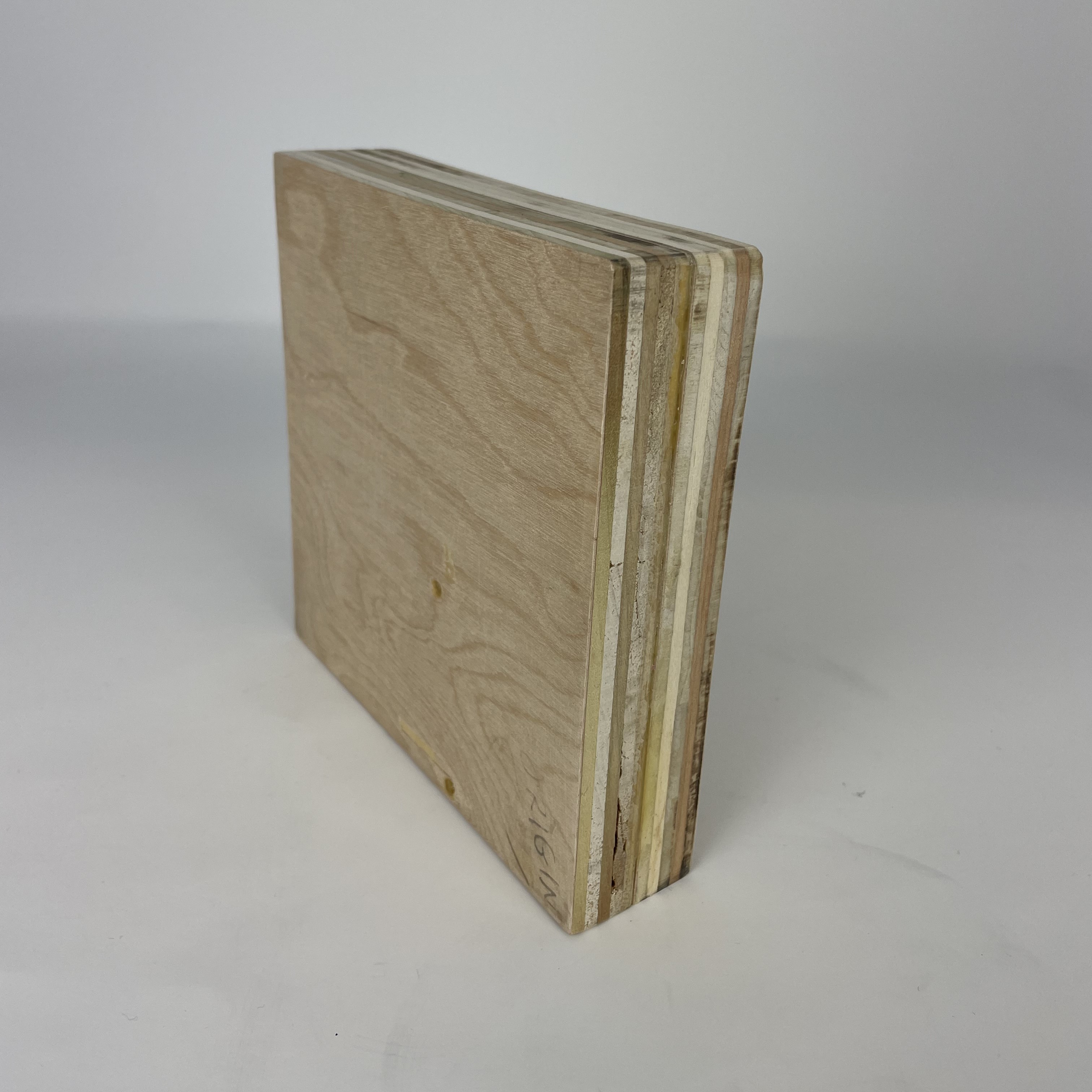

During the previous week, I created a mold for my hangboard. This week, I went to the Physics and Chem demo shop to grab some 3/4" plywood to laminate into 1.5" wood fit to host a hangboard. Atfer one of the Daniels helped me cut my wood, I applied a generous coat of glue between the two pieces, clamped it down on 3 sides, and let it cure overnight. The next day, I cut off the excess glue with an exacto knife and sanded down the sides on the belt sander.

-

Cast

-

Shaper

-

It then came the time to free my child from his prison and bring forth his spawn. I cut out the Smiski from the mold, splitting it into (mostly) two pieces. I left some portions around the limbs connected. I then put the mold in a new, identical cup and put silicon sealant along the edges of the cut mold to make sure it would not leak. That, at least, was super successful, and it did not leak. Before pouring in the silicon to make my babies, I forgot to powder the mold, which lead to some trouble taking it out of the mold. Though it was set well and the filled portions came out from the mold without issue, some portions of the mold did not fill due to the strange shape of the object. I added a second filling hole but still had trouble. As you can see, some of the limbs are missing. The final results are below.

-

Unfortunately, I was never able to complete the milling. I came to Ibrahim's OH to get help with the Shaper the night before the assignment was due, but he unfortunately did not know how to use it, and I did not want to use it alone so as to avoid injury.